Submitted by Joel on Sun, 08/26/2018 - 11:45

Forums:

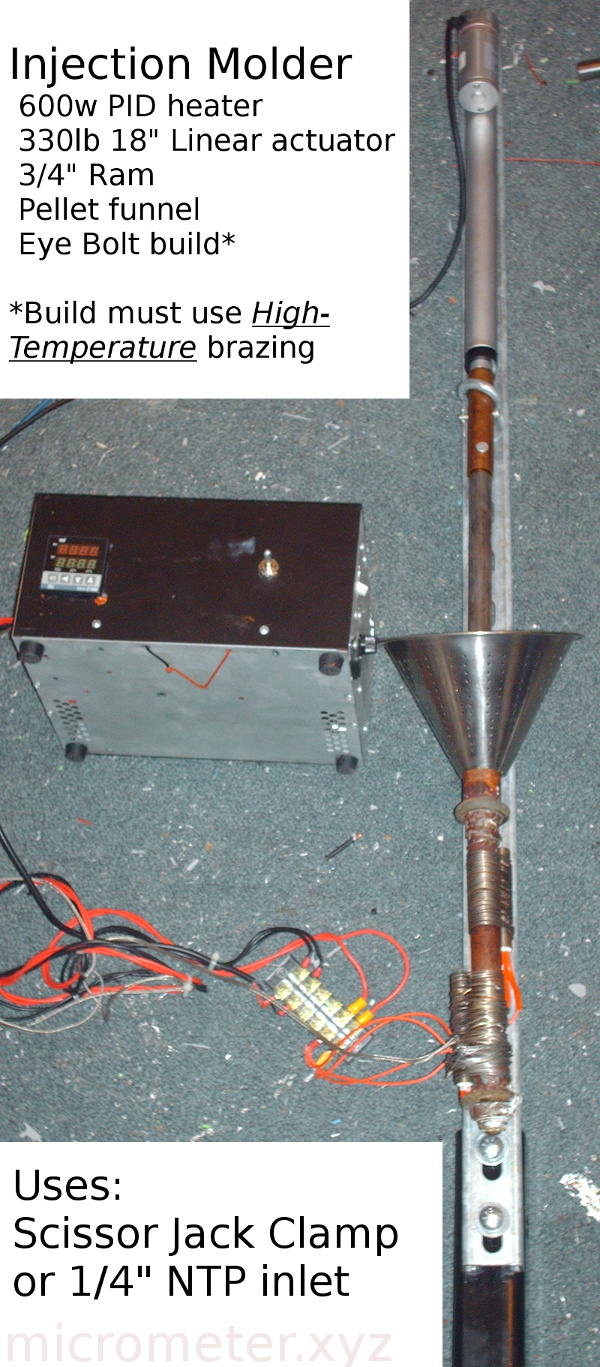

This is a simple Ram design is intended to be operated vertically. I have published it for another groups project, but do not plan to get into design details here due to the safety issues involved with high pressure molten plastics, and the dual 300W 120v line voltage heaters (the steel wire increases the thermal mass of the copper head).

- The mold should be pre-heated prior to being mounted onto this machine

- The pellets should be dried in a food dehydrator for a day prior to use

- Machine is brought up to temperature

- Ram withdrawn to open chamber fill gap (3 position switch up)

- Add pellets to melt zone to preheat

- Let sit for a few minutes, and top up chamber as needed (leave about 1/2" gap at the top to guide the ram down)

- Seat the heated mold, or connect to threaded insert (we used a large 1/8" ID hole)

- Drop the ram till mold vents erupt (shielding enclosure in case of molten-plastic steam blow-out should be added)

- Raise ram 1/8" to lower mold pressure, and spray mold with shop air to cool

- Carefully remove mold to cool a bit more (safe part removal temperature depends on plastic)

- Fully retract ram, and cycle process (or turn off heater if done)