Diode Laser engravers are quite common in specialty equipment. While I have posted in other forums about this subject, there are serious safety precautions people need to observe prior to powering up these devices:

- Two pairs of safety glasses for the range of possible output colors/spectra your laser emits (you get 1 chance to lose your eyesight from a reflective surface)

- Don't trust the glasses anyway, as some long-wave IR can penetrate a few cm into your flesh to cause internal burns (imagine a sunburn in 3D).

- Use a metal enclosure with a web camera to monitor for work-piece fires.

- Make sure to have a dry-chemical fire extinguisher next to the machine

- Diode lasers are expensive, but few know how to handle them without damage. Use a physical lock-switch to disable the laser with a key, and ensure the machine has a mushroom safety switch on the main power box.

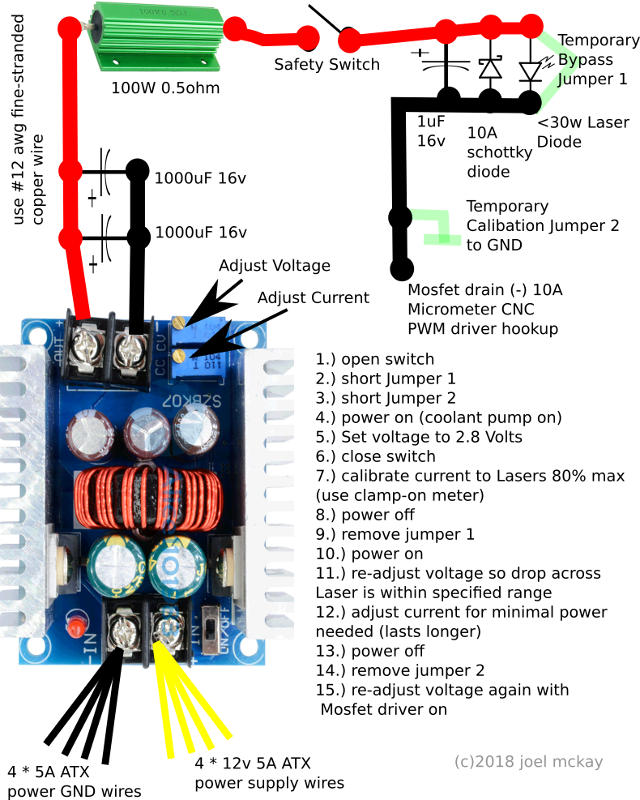

I have driven 35W fiber OSRAM laser modules using the following:

- Reverse 10A schottky diode on laser tabs, as they are very sensitive to static discharge and have minimal back-emf tolerance

- Inline 100W 0.5 ohm current limiting resister (10A 5v, used to adjust current without laser in circuit like a shunt)

- Modified the older ATX supply as typically these models had more current available on 5v rail.

- Adjust the regulated 5v line voltage down to the laser specs while measuring the drop across the mostfet, resister, and wires. This model specific mod also used 6 parallel wires to handle the various loads we tested.

For a below <30W diode lasers, I would recommend using a modern "300W 20A Step down Converter" low-ripple switching buck-regulator module off ebay with constant-current (CC) and constant-voltage (CV) adjustments. And add a few extra 1000uF 16v smoothing caps across the regulator output lines.

There are also constant-current LED ballasts available, but you need to closely inspect the laser manufactures specifications to see if it is safe to run above 2.8v. Usually high-power Diode lasers do not work like regular Diodes at all (a lot of people ignore this fact), and must also have active cooling with a water block (or TEC) to avoid warping the internal optics.

300W 20A Step down Converter example:

- Input Voltage: 12V DC

- Output Voltage: 2.8V DC

- Output Current: 10A max (start at 80% of lasers power)

- Efficiency: <95%

- Output Ripple: <=50mV (very important)

Note: At 2.8v this driver will max out at 5.6A (or about 16W output), so in order to get a maximum 10A (28W output limit) this design should parallel up two 100W 0.5ohm resisters.